VARIOFILM

VARIOFILM

We have a wide lineup of products to suit your needs, including heavy-duty grinding and finishing.

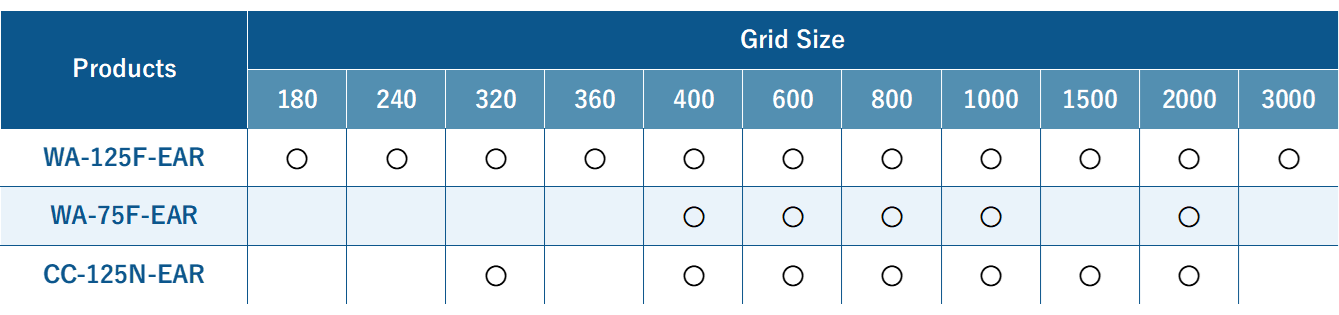

The base material is available in thicknesses of 125μ and 75μ, and the abrasives are aluminum oxide and silicon carbide. They can be processed to suit the material and shape of the workpiece.

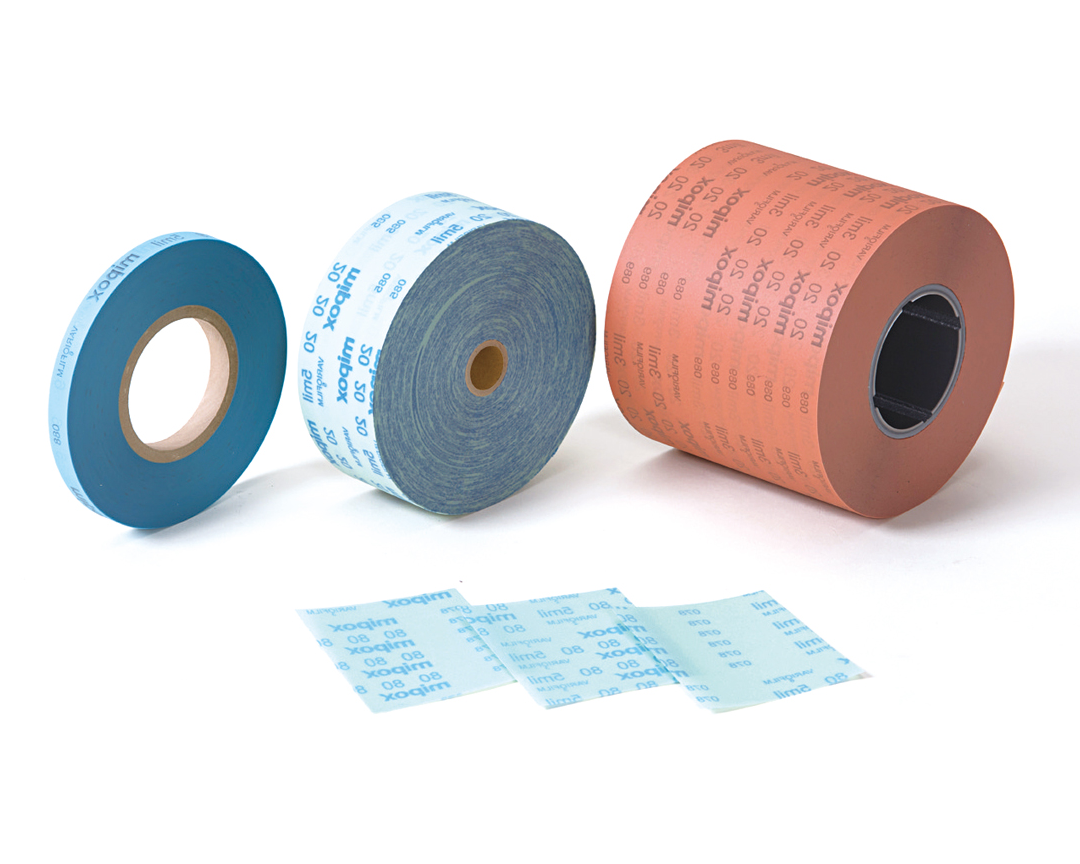

Product Shape

Applications

Product Features

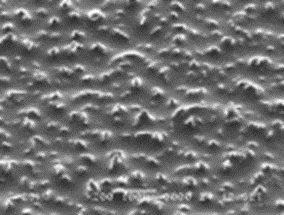

Abrasive particles are coated onto a smooth, tough polyester film substrate using electrostatic application to efficiently achieve a uniform finish. The back side has also been treated with an anti-slip coating to enhance grip.

Substrate: A polyester film substrate that is uniform in thickness, smooth and tough.

Resin: An adhesive with excellent water and oil resistance is used, providing excellent durability in both wet and dry polishing.

Abrasive grains: Abrasive particles with particle size controlled to the micron level provide precise polishing and finishing.

Coating: Coating is done using electrostatic application, making full use of MIPOX's coating technology.

VARIOFILM SEM

Product surface SEM image (×200)

Product Line-up

Application explanation

Application explanation

| Base material | : | WA | (3mil 75μ) | (5mil 125μ) |

| CC | (5mil 125μ) | |||

| Backside | : | Anti-slip coating |