Search by Solutions

Product

Search

Process Development and Transfer

Technology Transfer, Process Transfer

The variety of contract polishing services offered by Mipox also includes the transfer to customers' manufacturing lines "technology transfer (process transfer)", depending on their intent or project situation, such as transfer from prototyping to mass production, cost reduction, and quantity increase.

- Benefits of Outsourcing

- Process Development and Transfer Flow

- Comprehensive Process

- Examples

- Polishing Film Lineup

Benefits of Outsourcing Process Development

For customers, entrusting development to external experts not only helps obtain high-quality results but also ensures the customers' internal resources are rationally used.

We also handle contract services for development projects including a study of polishing methods, optimization of polishing conditions, selection of materials used for polishing, and performance evaluation of slurries and pads.

Process Development and Transfer Flow

Inquiry

Inquiries are accepted through the website contact form.

Consultation

Our sales representatives or technical department staff will go over your requirements. Confidentiality agreements will be signed according to the project content and circumstances.

Specification Definition

A series of processing specifications will be discussed. Specifications may be defined after prototyping and evaluation.

Prototyping & Evaluation

A series of processing operations (prototyping) will be conducted according to the contract content and specifications.

Process/Technology Transfer

Based on our processing expertise, we arrange and provide equipment and conditions so that optimal results can be achieved.

Support

Abrasive materials and consumables necessary for the stable operation of the customer's manufacturing line will be continuously supplied. Technical support will also be provided.

For technology transfer (process transfer), we arrange for the appropriate transfer of a complete set of items used in our polishing service such as polishing equipment, conditions, and processing expertise to your manufacturing line.

Process Development Enabling Handling from Start to Finish

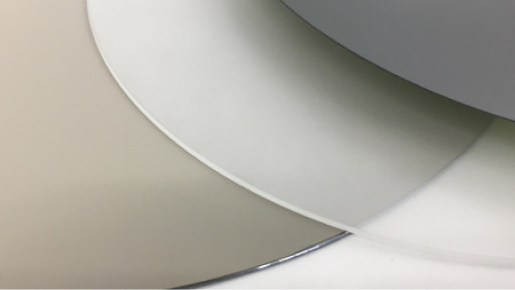

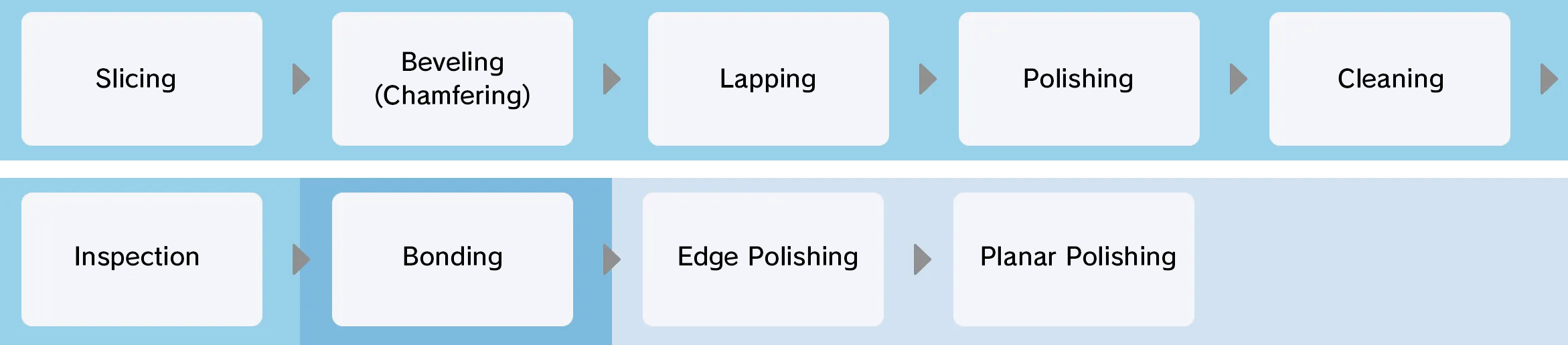

We can handle not only contract process development for single processes but also process development with all processes handled from start to finish based on edge and notch chamfering and each polishing process.

We support rational manufacturing line construction by smoothly connecting each process.

Example Wafer Polishing Process

Process Development Examples

<Polishing Line Construction>

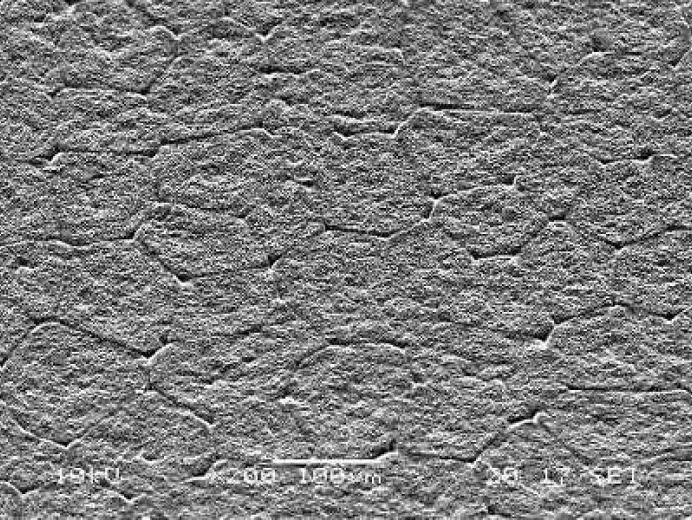

We received an inquiry regarding a customer's new project (new material wafer manufacturing). For new materials to which common wafer-making methods are difficult to be applied, we applied our polishing expertise. We received an order for total process development through multiple processing steps based on edge/notch chamfering and planar polishing.

<Material/Abrasive Evaluation>

We received an order for a project aimed at developing materials (selecting materials) for consumables used in general-purpose wafer polishing. Polishing equipment and evaluation equipment in our possession were used, and evaluation results at appropriate levels were submitted. The customer's development was supported.

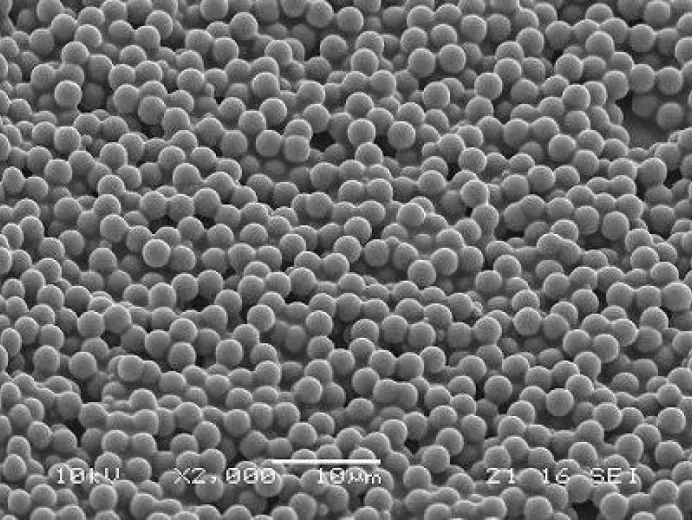

Polishing Film Lineup

The optimal type was selected from Mipox's extensive range of polishing film products. Using expertise in polishing film application accumulated over a long time, we provide polishing solutions that are optimal with all "polishing equipment, materials, and processing conditions" taken into account.

| Grain | New Mohs hardness |

Mesh / Grid Size(㎛) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fianl | 20000 | 15000 | 10000 | 8000 | 6000 | 4000 | 3000 | 2000 | 1500 | 1200 | 1000 | 800 | 600 | 400 | 320 | ||

| 0.03μ | 0.2μ | 0.3μ | 0.5μ | 1μ | 2μ | 3μ | 5μ | 9μ | 12μ | 15μ | 16μ | 20μ | 30μ | 40μ | 60μ | ||

| GC (SiC) |

13 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| WA (Al203) |

12 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| K (Cr203) |

8 | ● | ● | ● | |||||||||||||

| ROI (Fe203) |

7 | ● | ● | ||||||||||||||

| D | 15 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| CE (CeO2) |

9 | ● | ● | ||||||||||||||

| SO (CeO2) |

8 | ● | ● | ||||||||||||||

| Grain | Backside Treatment Back Coating |

Base Thickness | Mesh / Grid Size (㎛) | Application | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3000 | 2000 | 1500 | 1000 | 800 | 600 | 400 | 360 | 320 | 240 | |||||

| 5μ | 9μ | 12μ | 15μ | 20μ | 30μ | 40μ | 50μ | 60μ | 80μ | |||||

| WA (Al203) |

Present | 125μ | 5mil | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | Crankshaft Camshaft Metal Shaft |

| WA (Al203) |

Present | 75μ | 3mil | ● | ● | ● | ● | ● | Crankshaft Camshaft Metal Shaft |

|||||

| GC (SiC) |

Present | 125μ | 5mil | ● | ● | ● | ● | ● | ● | Crankshaft Camshaft Rubber Rolls Silicon Wafers (Edge trimming) |

||||

Mipox Technology Polishing Process Examples

CONTACT

Mipox, the polishing professional, will propose the best polishing solutions, materials, and tools to meet your needs.

Please feel free to contact us.