Final Polishing Film

Final Polishing Film

Controling the end face shape and achieving an ideal mirror finish in optical fiber connectors

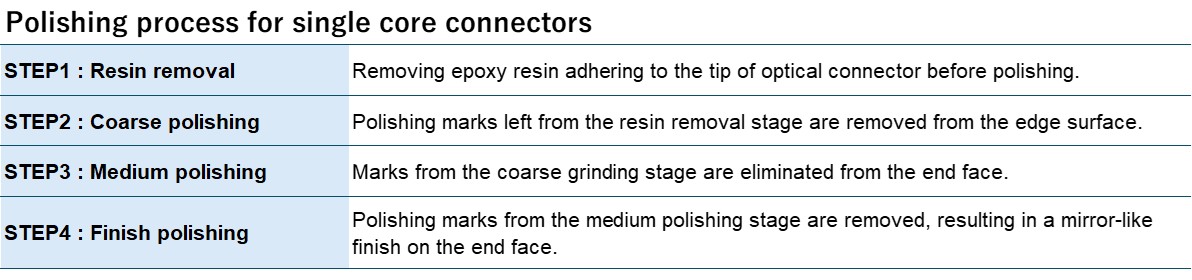

Final polishing film is developed for optical fiber polishing applications and primarily used for the final finishing of the end faces of single-fiber connectors.

Product Shape

Applications

Product Features

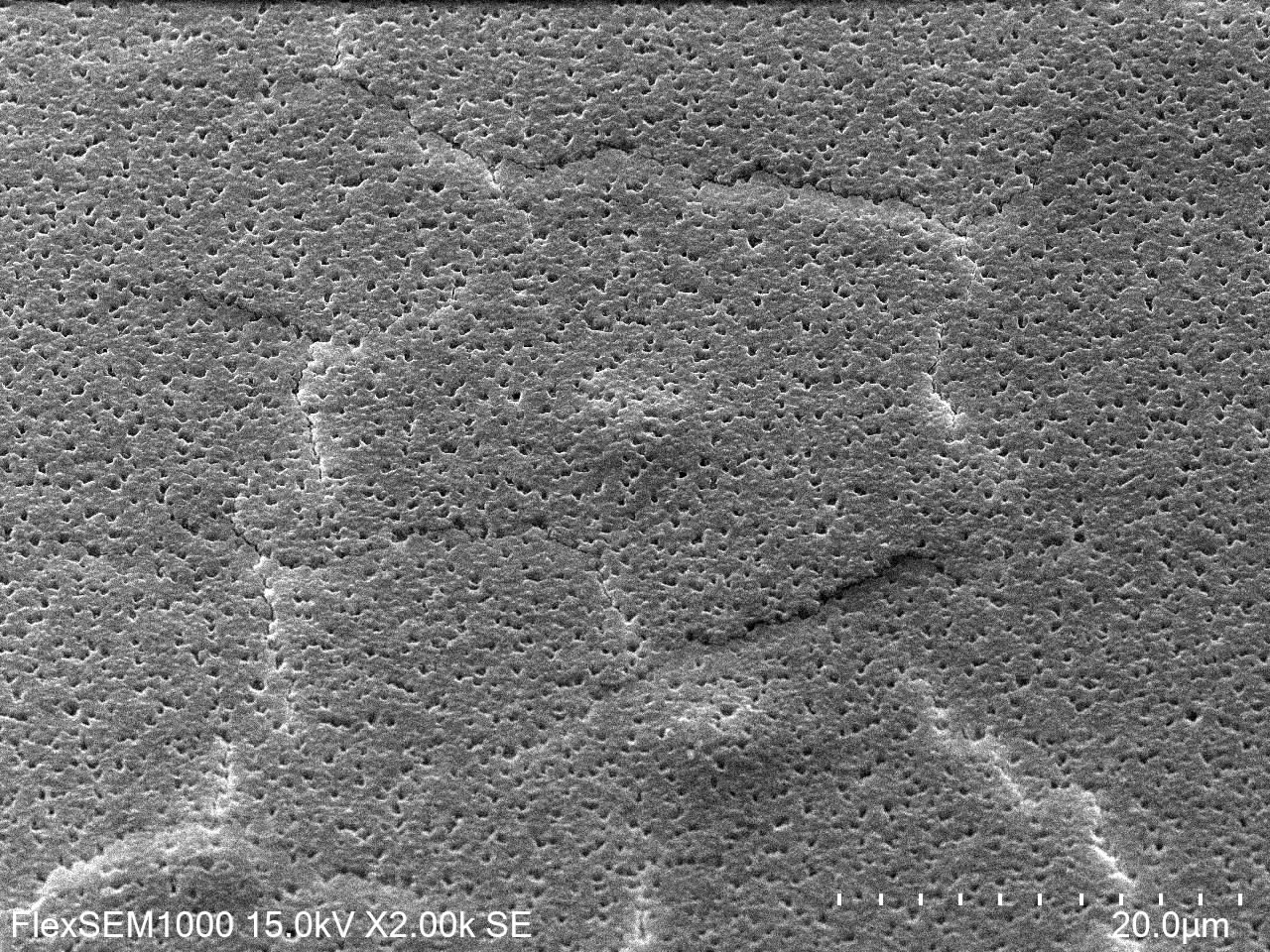

Mipox's unique silica and resin mixture design achieves high-quality finishing with durability.

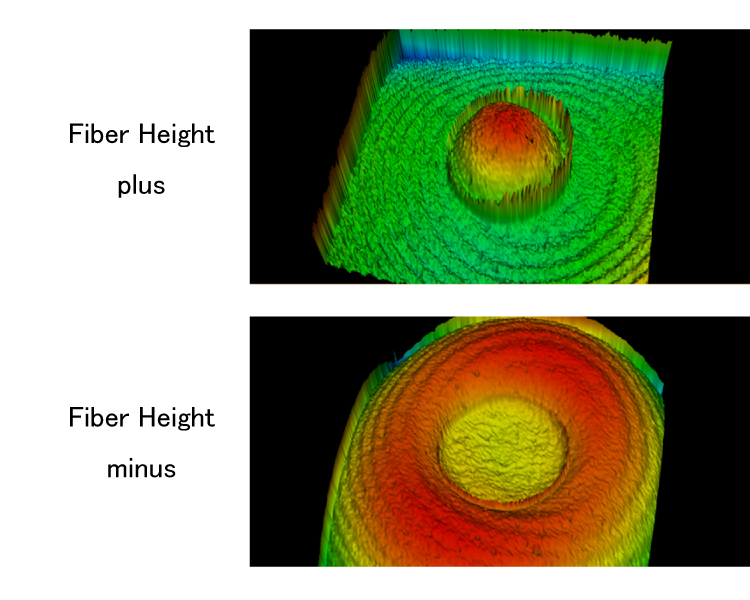

The polishing mechanism, in which silica abrasive is liberated during polishing to form a slurry, makes it possible to control the protruding shape of the fiber and meet various requirements for the fiber shape after finishing.

It is possible to achieve a high-quality mirror finish on the end of optical fiber.

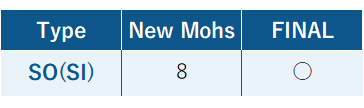

There are multiple lineups that correspond to the characteristics of polishing and fiber height to meet various requests.

Ultimas PRO

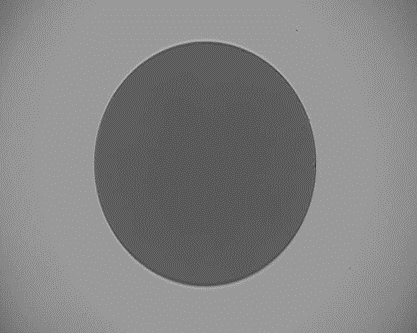

Product surface SEM image (×2000)

Product Line-up

Reference information of polishing characteristics

The above is a guideline when polishing with Mipox's recommended process. Since there are multiple lineups, Mipox can make suggestions including the process according to desired parameters.

026Ultimas PRO, in which the protruding height of the optical fiber at the end face of the single-core connector is higher than that of the conventional 026Ultimas (smaller fiber concavity), is also available, allowing control of the concave and convex sides of the fiber height.

Image of single-core connector after finish polishing. The design of silica and resin blending has realized both mirror finish on the end face and high durability.