Film Magic Tack

Film Magic Tack

Because it is a film-based product, it can achieve a finer and more uniform finish after polishing than paper-based products.It is also more durable, meaning there is less need to replace the product.

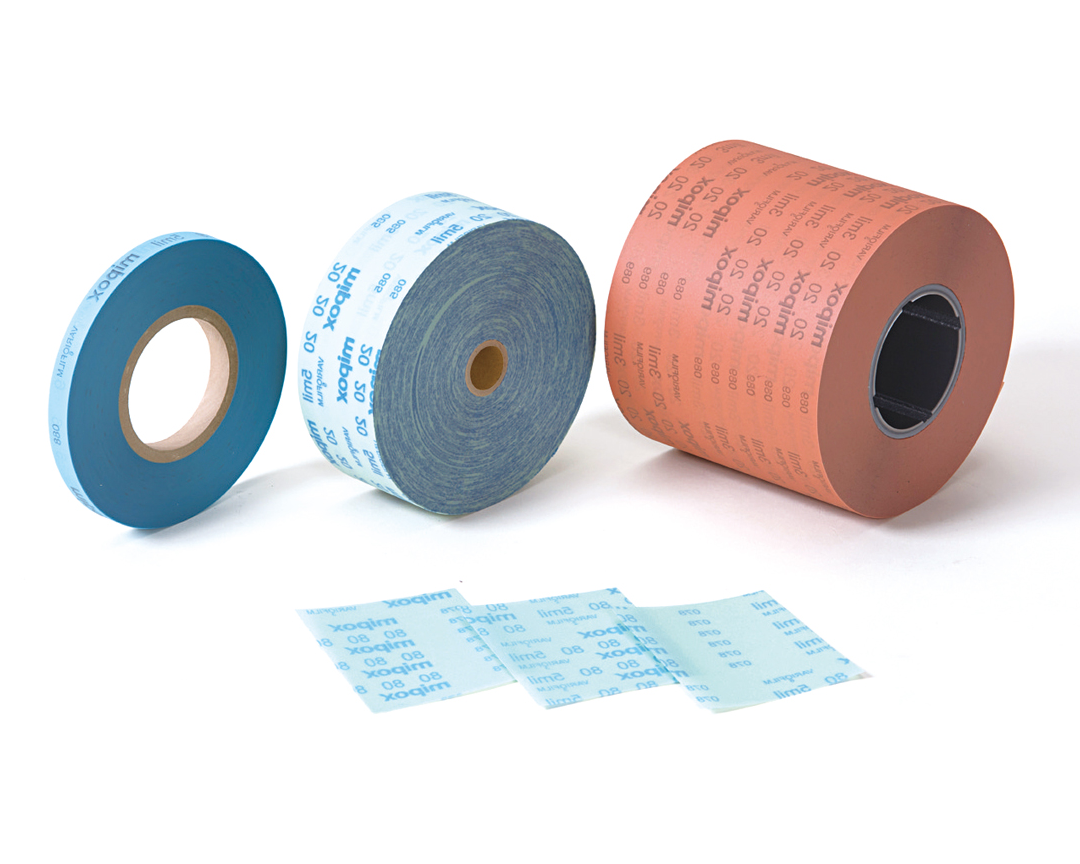

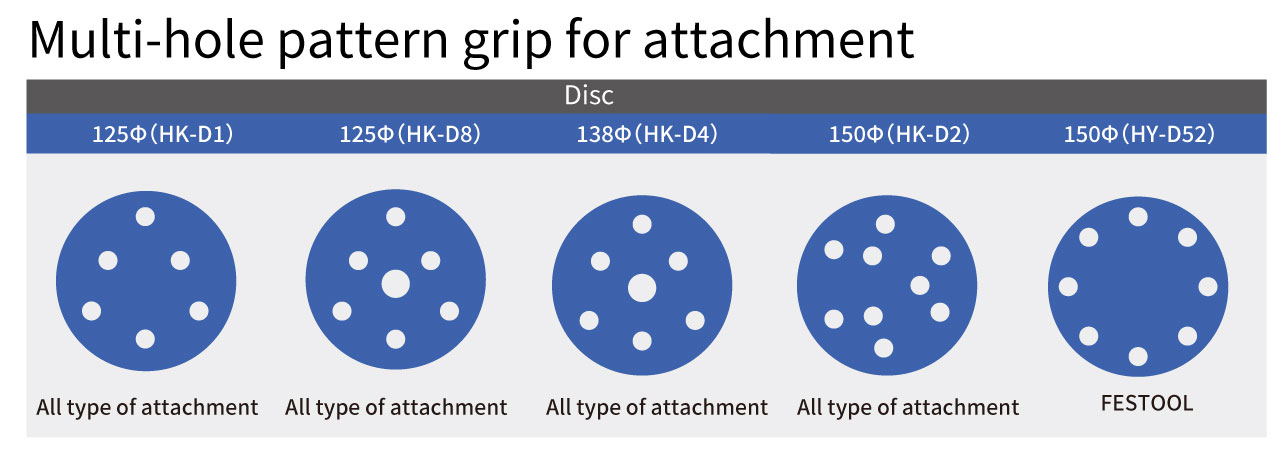

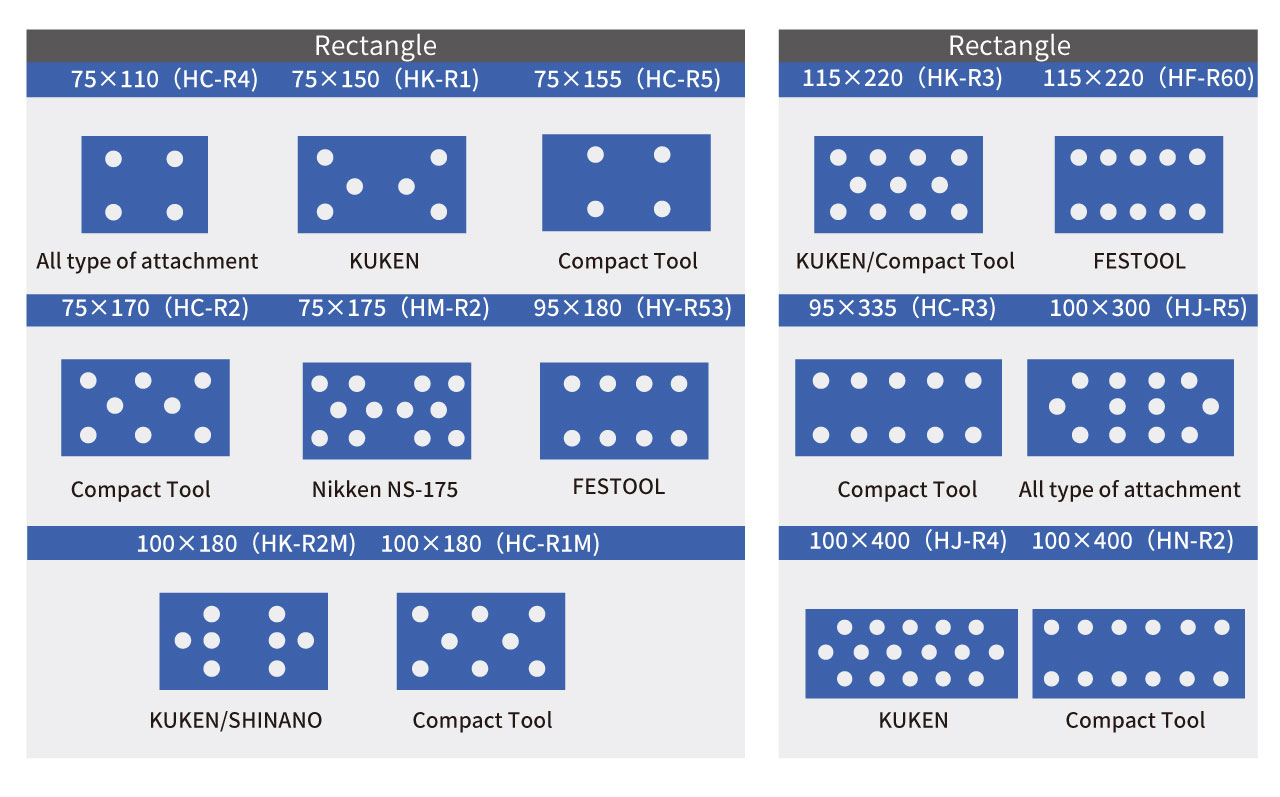

Product Shape

Applications

Product Features

Film Magic Tack

1: High smoothnessThe film base is very smooth and uniform, so a uniform finish can be obtained.2: Excellent durabilityThe film base is less likely to tear than paper or cloth, and can withstand long-term use. It is also water-resistant, so it can be used in wet polishing.3: High-precision polishingThe film base is less likely to stretch and has high dimensional stability, making it suitable for work that requires high-precision polishing.4: Easy replacementThe use of Velcro makes it easy to attach to and replace the polishing machine, improving work efficiency.5: Multi-purposeIt is suitable for a variety of materials and applications, such as woodworking, metal, plastic, and pre-painting preparation.Film Magic Polishing Paper is particularly useful for work that requires a uniform finish and durability.◎WRAF: Because it is a film base, a uniform finished surface can be obtained. This is a film product that emphasizes grinding ability.◎WTCF: Because it is a film base, a uniform finished surface can be obtained. With finer grit, it is ideal for polishing painted surfaces in the final process.◎SUWF: Because it is an open coat, there is less clogging. The use of tough abrasives provides excellent durability and high grinding performance.

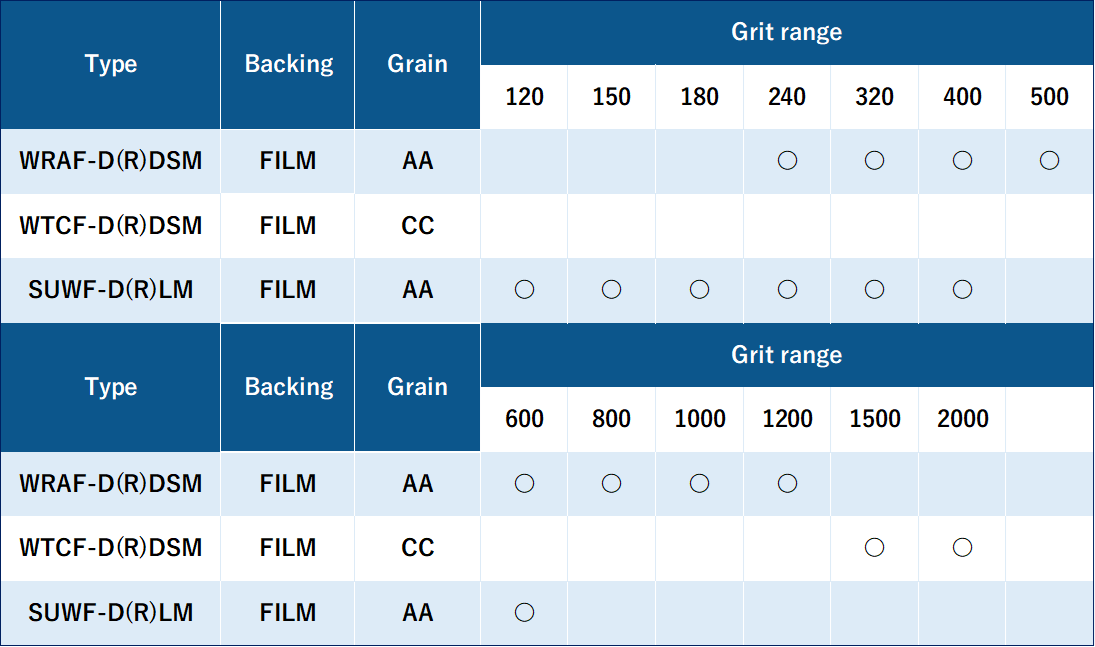

Product Line-up

Application explanation

◎It is suitable for tasks that require high-precision finishing, such as automobile repair (plaster and putty), woodworking of furniture, manufacturing of electronic devices, finishing of non-ferrous and metal parts, preparation of the base before painting, and processing of resin molded products and plastic products. It is particularly useful when a smooth and uniform surface treatment is required. ◎The main uses of film-based abrasive paper are as follows. ◎It is used for finishing and polishing of metal surfaces: It is used for surface treatment of metal parts, such as removing rust and polishing. ◎It is used for pre-treatment of automobile painting: It is used for preparing and polishing the painted surface to create a smooth and uniform base. ◎It is used for surface finishing of resin and plastic: It is used for removing burrs and creating a glossy surface. ◎It is used for surface finishing of wood: It is used to smooth the surface of furniture and building materials and prepare the base for painting and varnishing. ◎It is used for finishing of precision parts: It is used for polishing parts that require a precise finish. ◎It is used for parts manufacturing of aircraft and medical equipment: It is used for polishing parts that require a high‐precision finish. ◎It is used to polish the surfaces of gemstones and precious metals to obtain a luxurious finish.【Specifications】It is ideal for heavy-duty grinding and weld polishing of automotive parts, aluminum die castings, stainless steel, etc.Applications include deburring carbon steel, ordinary steel, and stainless steel, removing weld beads, and removing spot weld marks.Objects that can be polished include turbine blades, automotive parts, castings, forgings, dies, etc.